A Complete Guide to Laser Engraving and Etching on Stone

CODE

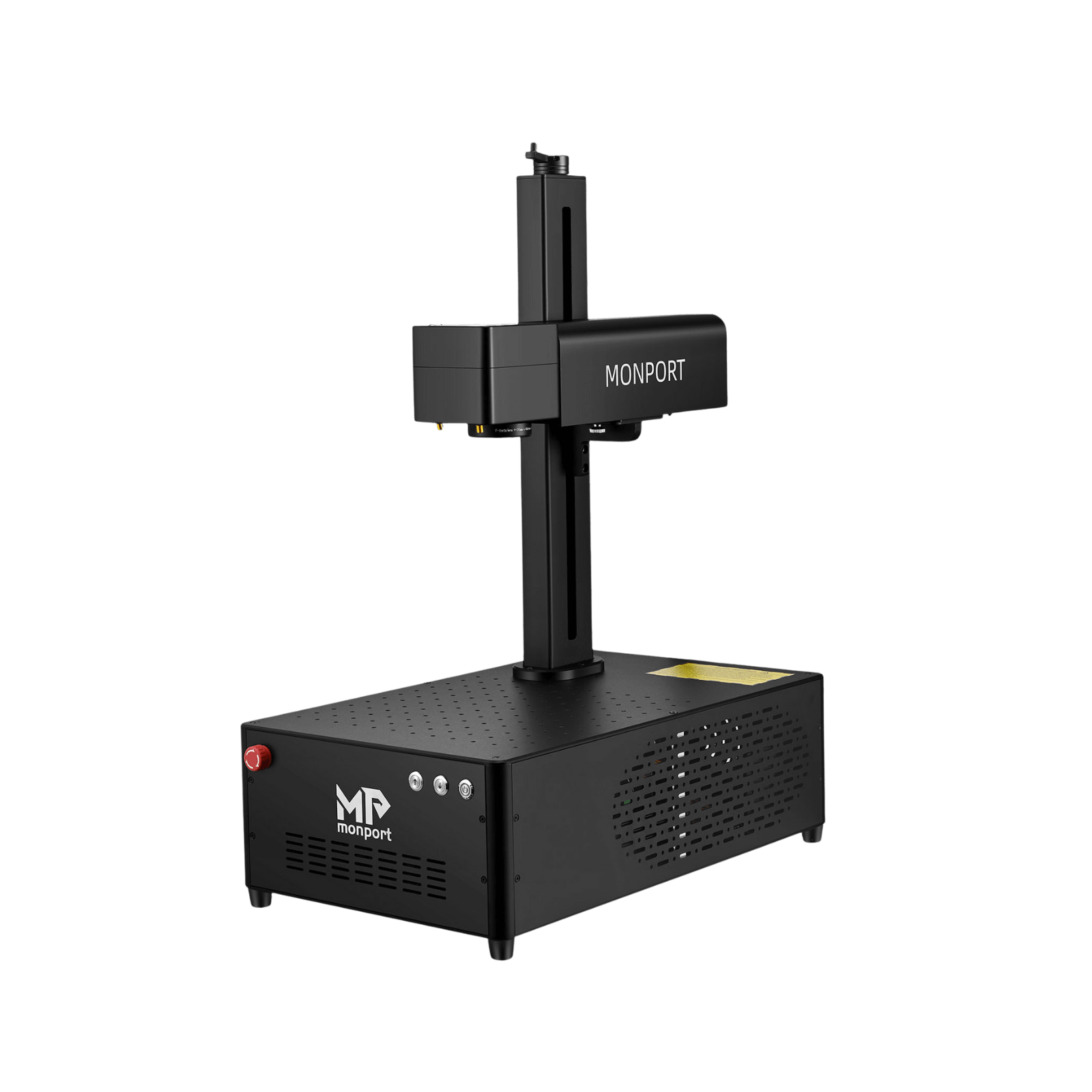

If you're looking to add a personal touch to your stone projects, you might consider laser engraving or etching in stone. Laser engraving and etching is the process of using a laser beam to remove material from the surface of a stone, creating a design or image. This process is precise and clean, and it can be used on a variety of stones, including granite, marble, and slate. In this guide, we will discuss the Monport 150W CO2 Laser Engraver & Cutter and how it can be used for laser engraving and etching on stone.

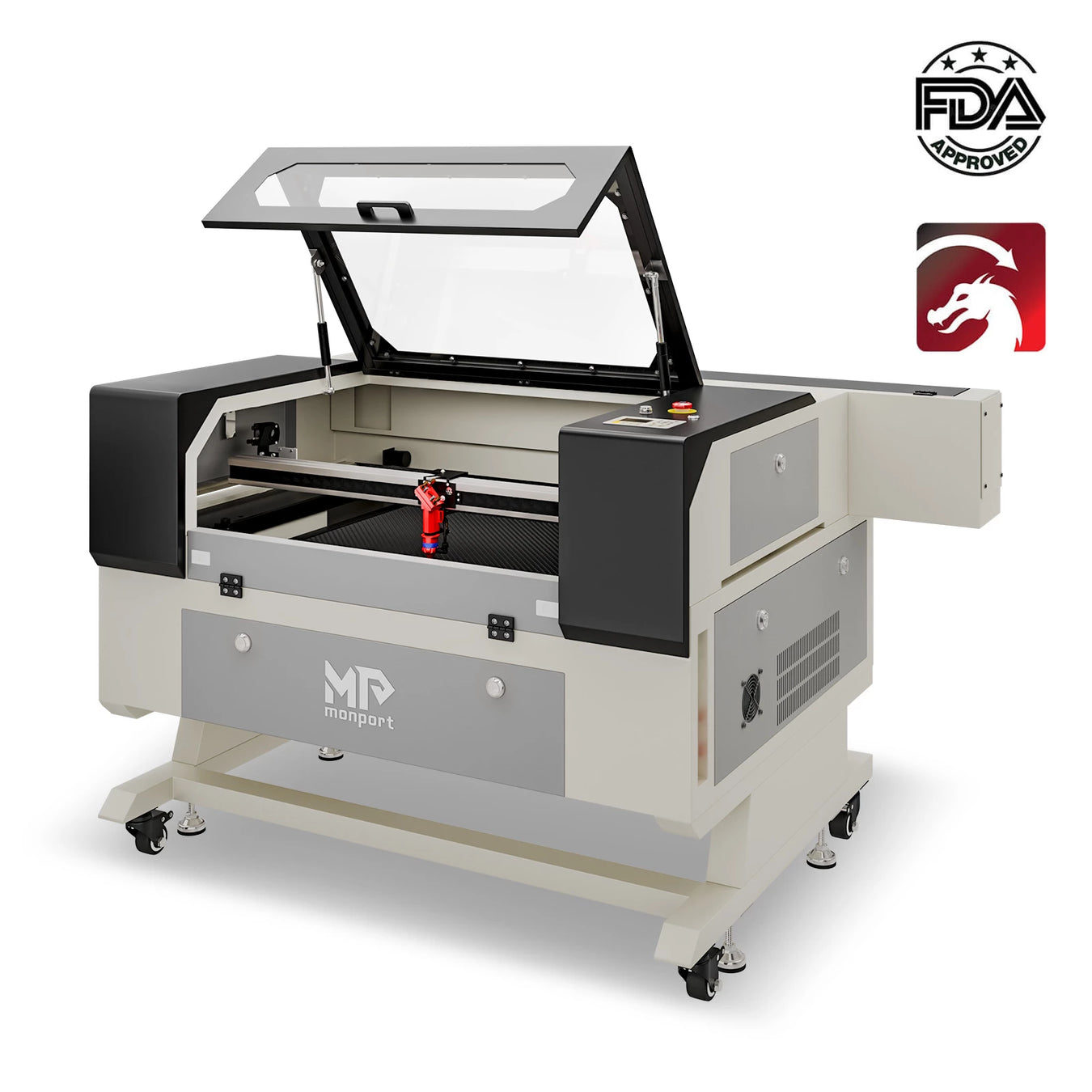

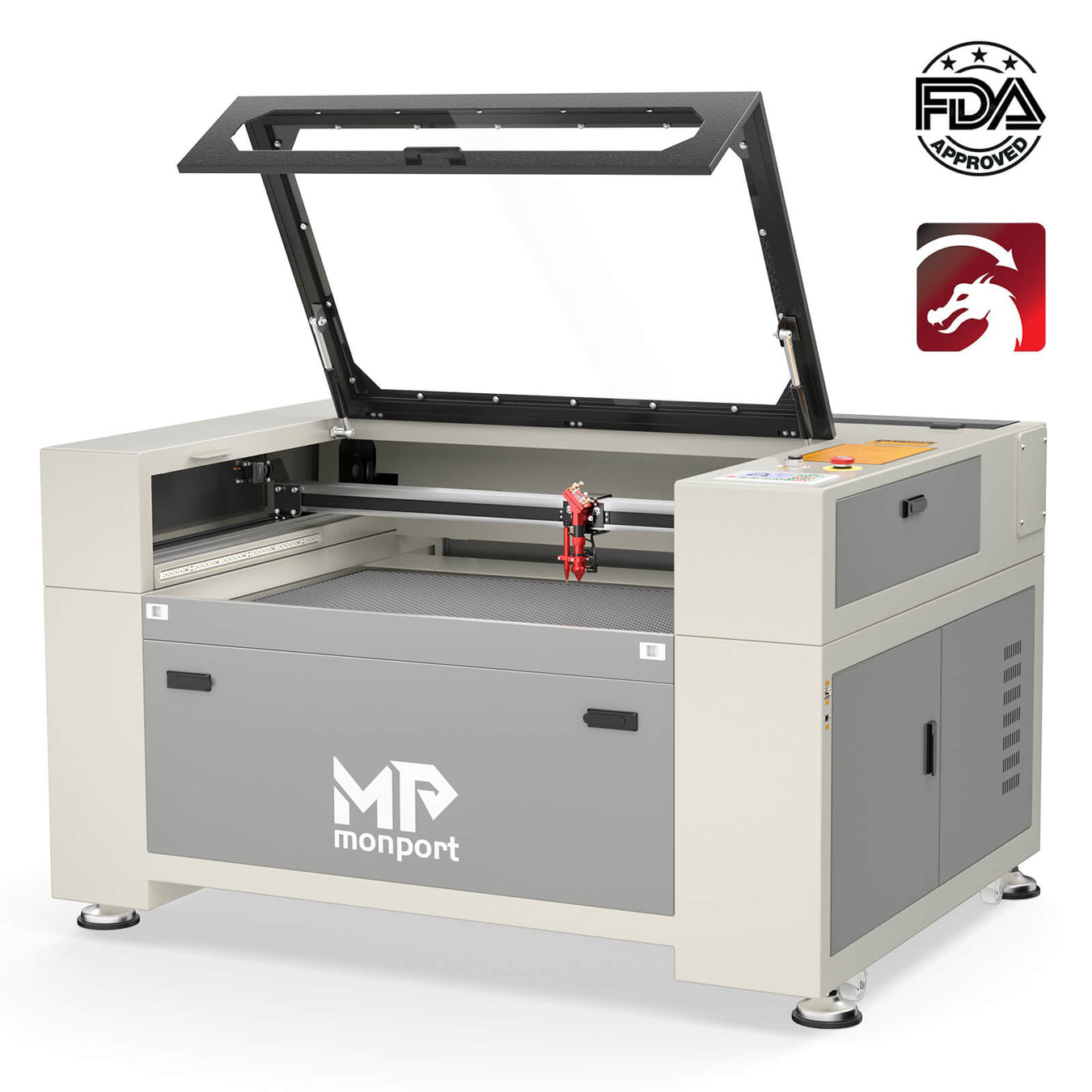

Monport 150W CO2 Laser Engraver & Cutter (64" x 40") with FDA Approved

Monport 150W CO2 Laser Engraver & Cutter (64" x 40") with FDA Approved

Getting Started: Understanding the Monport 150W CO2 Laser Engraver & Cutter

The Monport 150W CO2 Laser Engraver & Cutter is a powerful machine that can be used for a variety of tasks, including laser engraving and cutting. This machine has a large work area of 64" x 40" and is FDA approved for use in the United States. It has a high-precision laser beam that can be adjusted for power and speed, allowing you to create intricate designs and patterns on stone surfaces.

Key Features of the Monport 150W CO2 Laser Engraver & Cutter

- Large work area of 64" x 40"

- High-precision laser beam for detailed engraving and etching

- Adjustable power and speed settings for customized projects

- FDA approved for use in the United States

- Can be used for a variety of materials, including stone, wood, and acrylic

Laser Engraving and Etching on Stone: Tips and Tricks

Choosing the Right Stone for Laser Engraving and Etching

Not all types of stone are suitable for laser engraving and etching. It's important to choose a stone that has a consistent color and texture, as this will ensure that the laser beam is able to make a clean, precise cut. Granite, marble, and slate are popular choices for laser engraving and etching because they have a smooth, even surface.

Proper Preparation of the Stone

Before you begin laser engraving or etching on stone, it is important to properly prepare the stone surface. This includes cleaning the stone surface thoroughly and removing any dirt or debris that may be present. Additionally, you may want to apply masking tape to the surface of the stone to protect it from the laser beam and create a guide for your design.

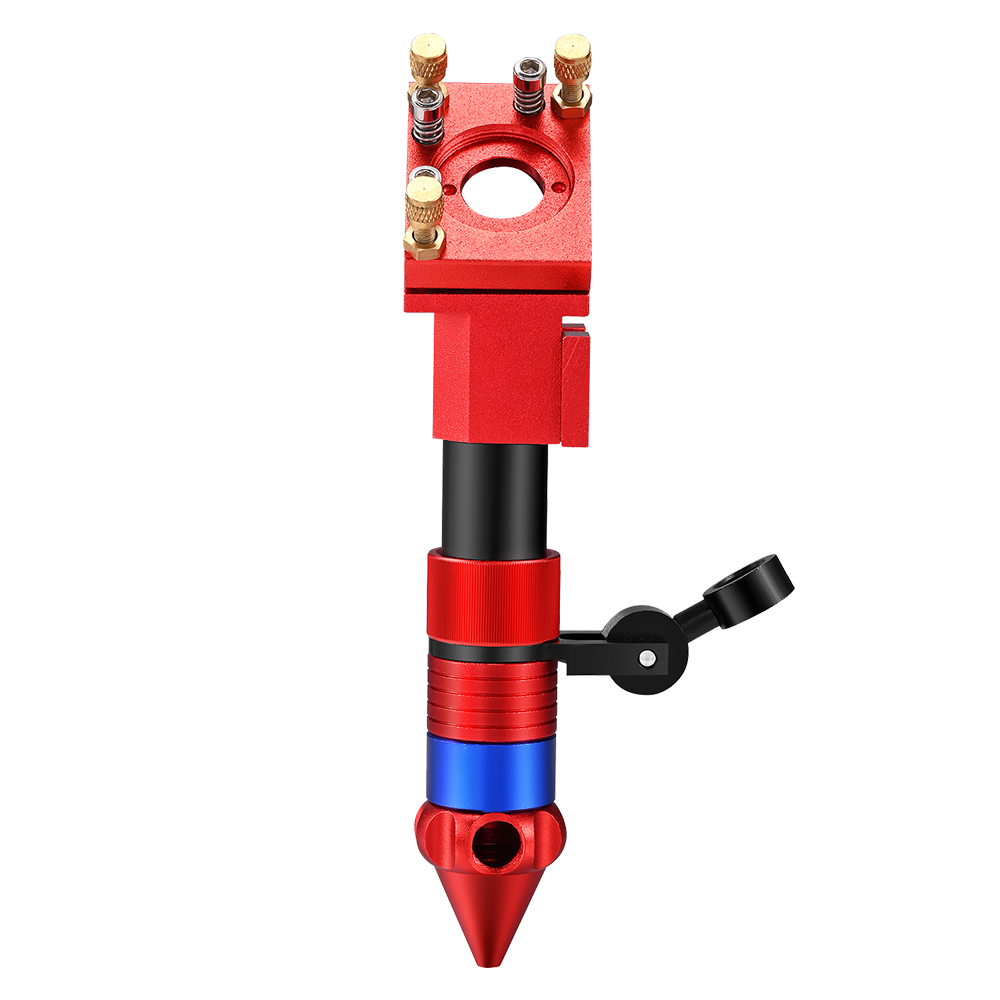

Adjusting the Laser Settings

The Monport 150W CO2 Laser Engraver & Cutter has adjustable power and speed settings, which can be used to customize your engraving and etching projects. When working with stone, it's important to start with a lower power setting and increase it gradually to avoid damaging or chipping the stone surface. Additionally, you may want to adjust the speed of the laser beam to achieve different effects on the stone surface.

Design Considerations for Laser Engraving and Etching on Stone

When designing projects for laser engraving or etching on stone, it's important to keep in mind the limitations of the process. Because laser engraving and etching is a subtractive process (meaning material is removed from the surface), intricate designs with fine details may not be possible. Additionally, designs with a lot of small, narrow lines or curves may not be visible on the stone surface.

FAQs

How deep can the laser engrave into the stone?

The depth of the laser engraving depends on several factors, including the hardness of the stone and the power of the laser beam. Typically, a laser engraving on stone can be up to 0.025" deep.

Is the Monport 150W CO2 Laser Engraver & Cutter difficult to use?

The Monport 150W CO2 Laser Engraver & Cutter is easy to use and can be operated by anyone with basic computer skills.

Can the Monport 150W CO2 Laser Engraver & Cutter be used on other materials besides stone?

Yes, the Monport 150W CO2 Laser Engraver & Cutter can be used on a variety of materials, including wood, acrylic, and plastic.

Important Details to Consider

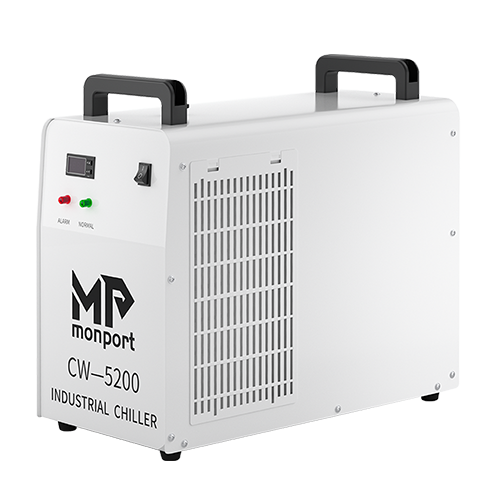

When using the Monport 150W CO2 Laser Engraver & Cutter for laser engraving or etching on stone, it's important to consider safety precautions. The laser beam can be harmful to human eyes and skin, and it's important to wear protective equipment, such as goggles and gloves, when operating the machine. Additionally, it's important to follow proper ventilation procedures to avoid inhaling any harmful fumes that may be produced during the engraving or etching process.

Takeaways

Laser engraving and etching on stone can add a personal touch to your stone projects and create a unique design or image. The Monport 150W CO2 Laser Engraver & Cutter is a powerful machine that makes it easy to achieve precise and detailed cuts on stone surfaces. When working with stone, it's important to properly prepare the surface, choose the right stone, and adjust the laser settings for best results.

Conclusion

We hope this guide has been helpful in understanding how to use the Monport 150W CO2 Laser Engraver & Cutter for laser engraving and etching on stone. With the right preparation and careful consideration of design, you can achieve beautiful and unique designs on a variety of stones. Remember to always follow proper safety procedures and adjust the laser settings accordingly for the best results.

Leave a comment