Crafting Exquisite Keepsakes: How Laser Cut Jewelry Boxes Elevate Your Business with Monport

CODE

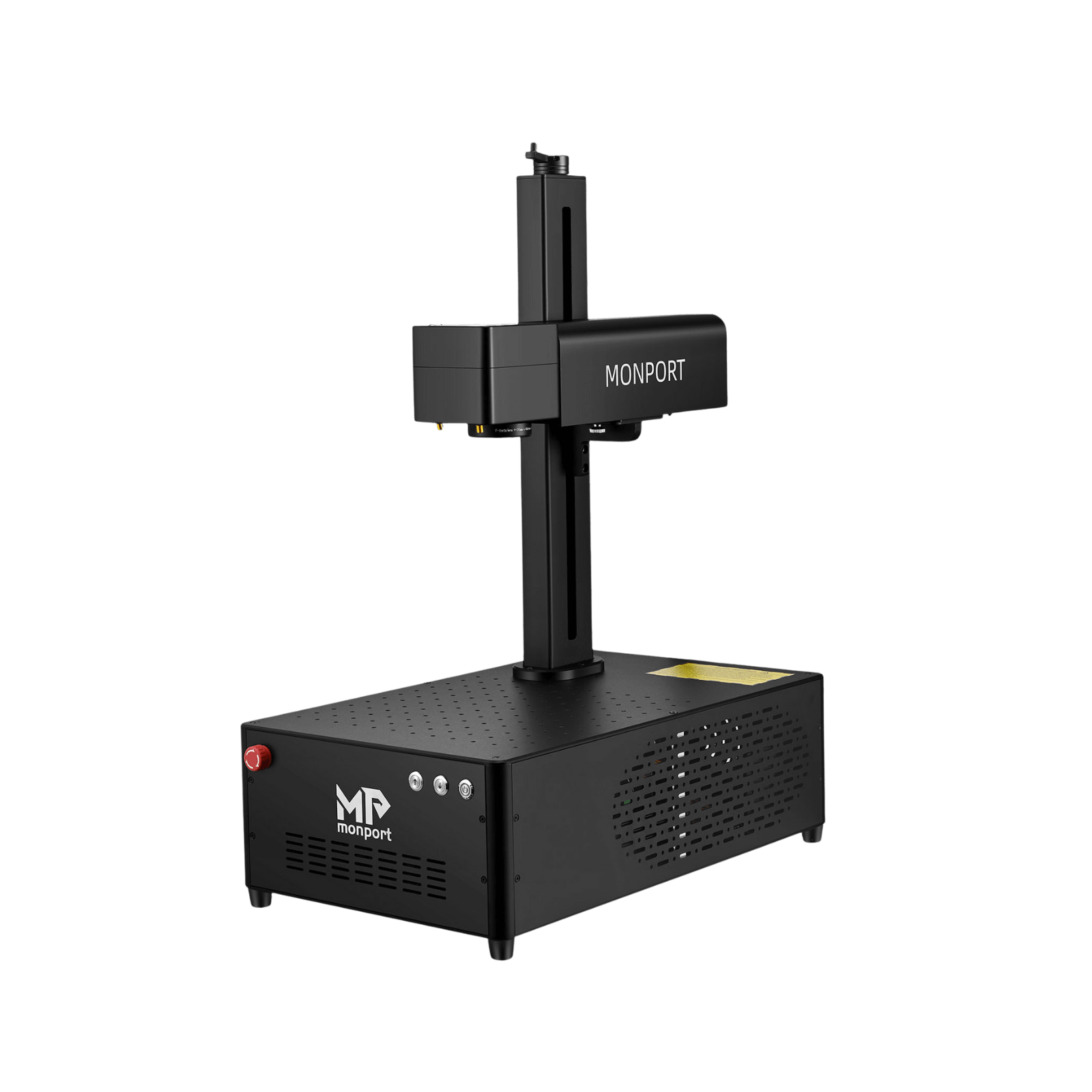

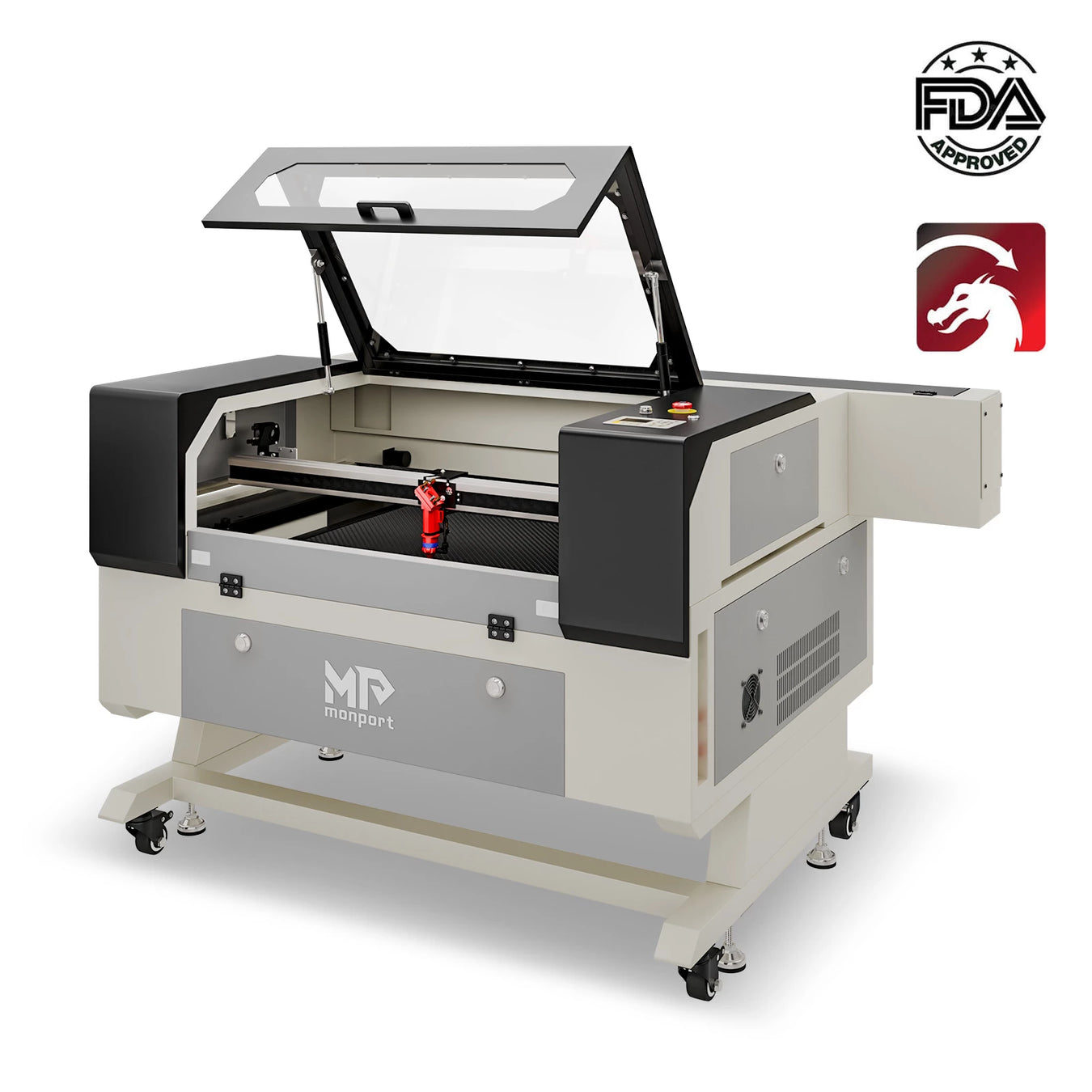

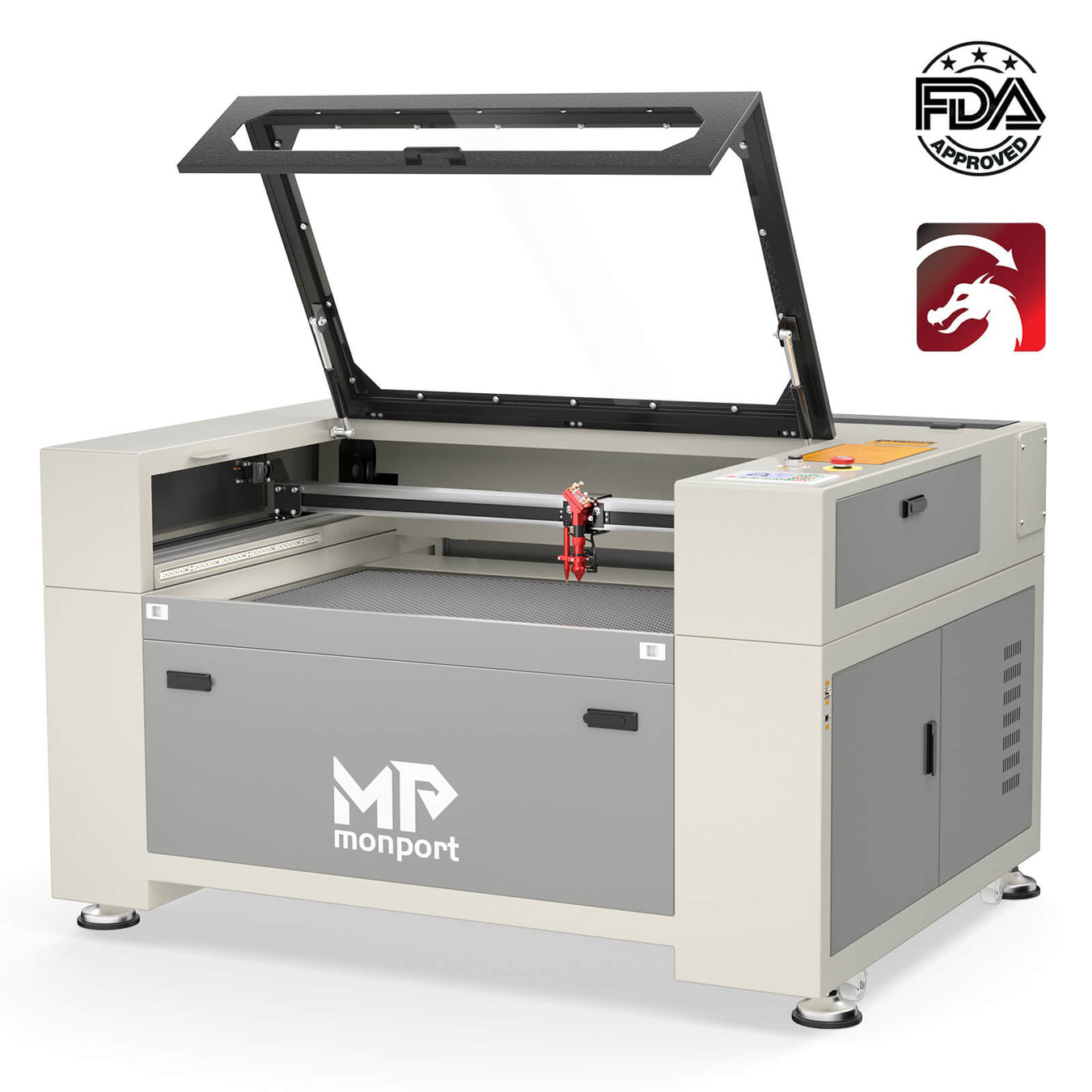

For small businesses in the jewelry industry, presentation is everything. A beautifully crafted laser cut jewelry box can elevate even the simplest piece, transforming it into a treasured possession. This blog delves into the world of laser cut jewelry boxes, exploring the advantages of using a CO2 laser equipment like the Monport 80W CO2 Laser Engraver & Cutter, and how it can empower your business to create unique and personalized packaging solutions.

Monport 80W CO2 Laser Engraver & Cutter (24" x 16") with Autofocus

Beyond the Bulky Box: The Beauty of Laser Cut Jewelry Boxes

Traditional jewelry boxes can often feel bulky and generic. Laser cut jewelry boxes offer a refreshing alternative, allowing you to create intricate designs, personalize each box, and add a touch of luxury to your jewelry presentation. Here's why laser cut jewelry boxes are a game-changer for your business:

-

Unmatched Design Versatility: CO2 laser equipment, like the Monport 80W, provide exceptional design flexibility. You can create intricate patterns, logos, or even custom text onto the jewelry box material, allowing you to develop a unique brand signature for your packaging.

-

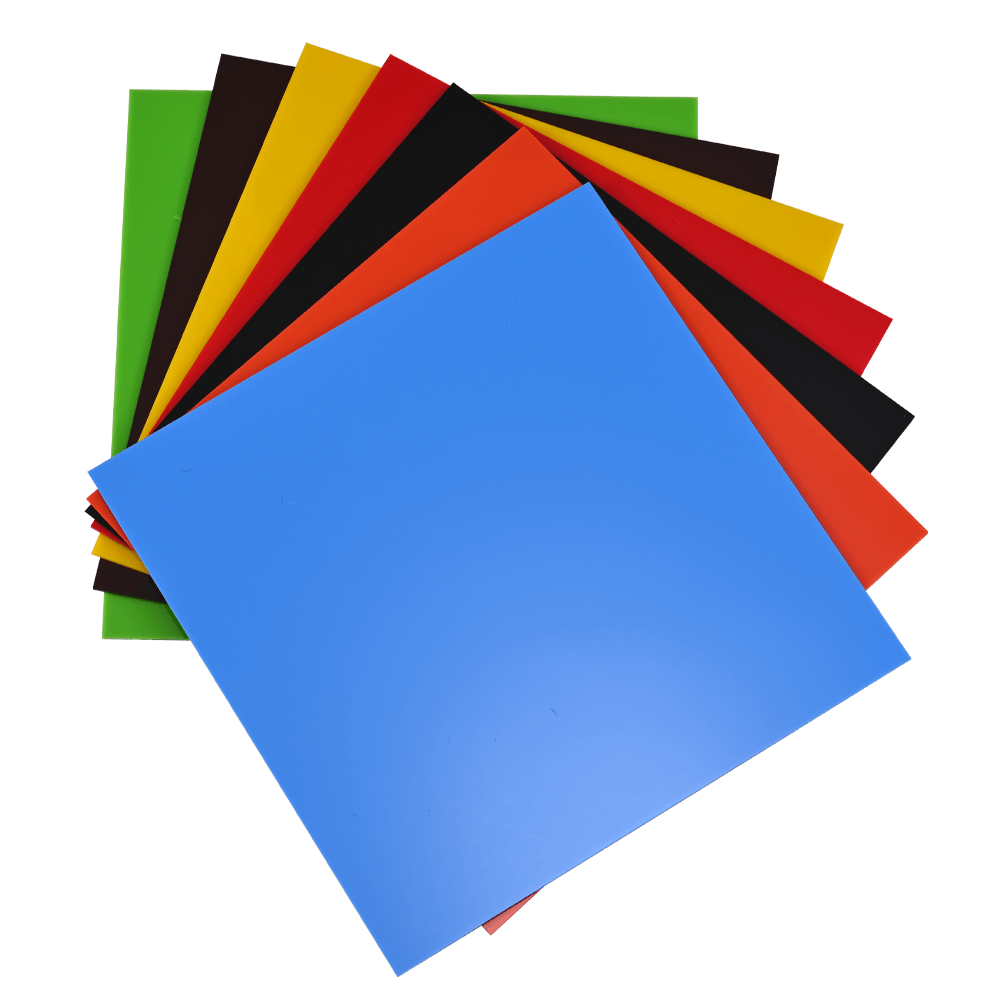

Material Options for Every Style: CO2 laser equipments offer compatibility with various non-metallic materials, including wood, acrylic, and even leather. This allows you to choose the perfect material to complement your jewelry style, whether it's a rustic wooden box for handcrafted pieces or a sleek acrylic box for contemporary designs.

-

Personalization Made Easy: The ability to laser engrave names, initials, or even short messages onto the laser cut jewelry box adds a personal touch, transforming each box into a unique and sentimental keepsake. This personalization can be a powerful marketing tool, fostering customer loyalty and encouraging repeat business.

-

Cost-Effectiveness: Investing in a CO2 laser equipment like the Monport 80W can be surprisingly cost-effective in the long run. Once you have the machine and design files, creating custom laser cut jewelry boxes becomes an efficient and affordable process, allowing you to maintain healthy profit margins.

The Monport 80W CO2 Laser Engraver & Cutter: Your All-in-One Laser Equipment

The Monport 80W CO2 Laser Engraver & Cutter is specifically designed to empower businesses like yours to create high-quality, personalized products. Here's how its features translate to crafting exquisite laser cut jewelry boxes:

-

For Larger Engraving Projects: The Monport 80W laser equipment boasts a spacious 16" x 24" work area, allowing you to create laser cut jewelry boxes in various sizes to accommodate different types of jewelry. The four-way pass-through feature even allows for engraving on materials that extend beyond the workbed, perfect for larger box designs.

-

High-Performance Laser Beam: This engraver utilizes a high-efficiency laser beam, meticulously developed through joint research by Monport and Yongli. This laser offers a remarkable 12,000 hours of operation and delivers a superior actual RP (Rasterization Power) compared to competitors with similar laser tube specifications, ensuring clean and precise cuts on your chosen material.

-

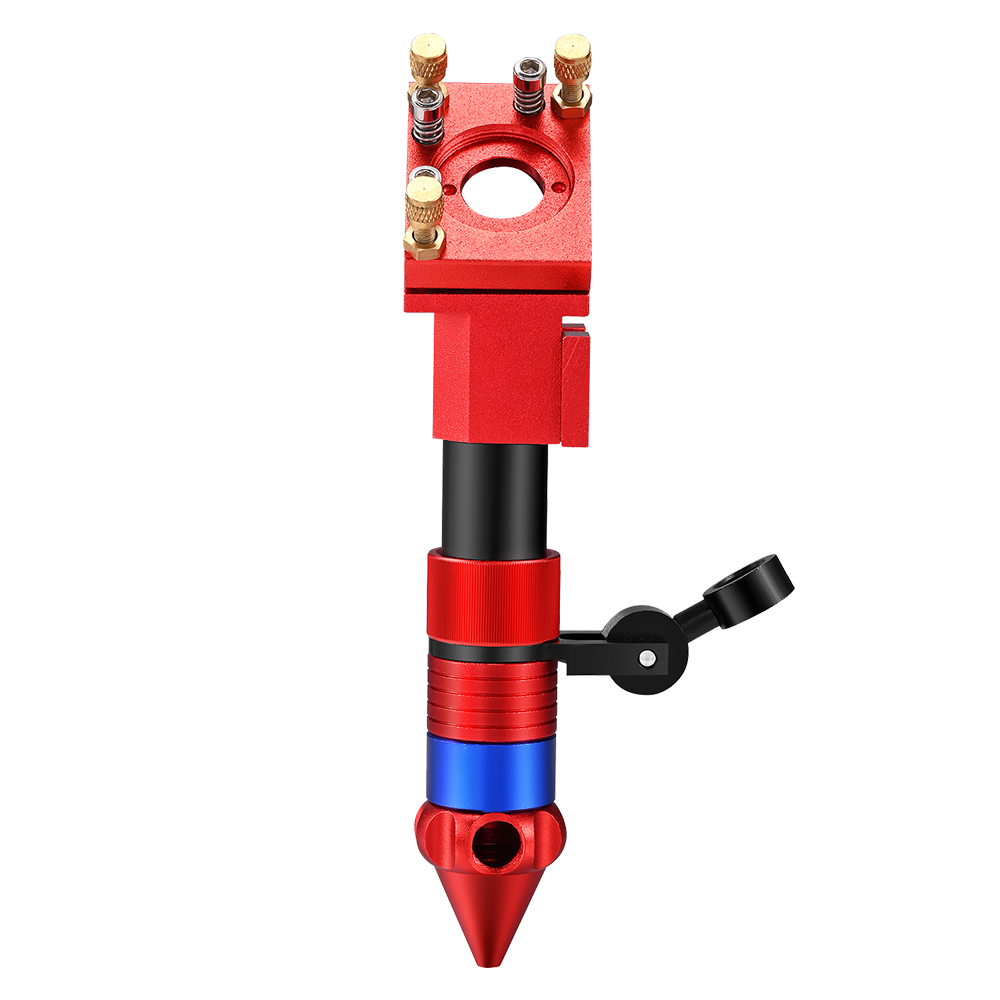

Advanced 4-in-1 Laser Head: The Monport 80W features a revolutionary 4-in-1 laser head, combining laser emission, autofocus, air assist, and red light indication. This ensures precise cutting and engraving while also streamlining your workflow. High-specification focusing lenses produced by Wavelength Optoelectronics further enhance the engraving and cutting experience.

-

Intelligent Control Panel: The user-friendly control panel offers intuitive control over auto-focusing, Z-axis movement, and air assist functions. You can even modify layer parameters directly on the control panel with auto-saving functionality, making adjustments a breeze. Additionally, the system supports power-off resume and provides accurate work time previews, allowing for efficient workflow management.

-

Comprehensive Safety Features: The Monport 80W prioritizes user safety with features like an emergency stop button, independent laser control with a dedicated key, and cover protection that halts operation when opened. The fireproof window allows for safe observation of the engraving process, while built-in ventilation ensures efficient smoke removal.

From Concept to Creation: Step-by-step guide (Laser Cut Jewelry Boxes)

With the Monport 80W CO2 Laser Engraver & Cutter, creating stunning laser cut jewelry boxes is easier than ever. Here's a glimpse into the creative process:

-

Design: Develop your unique jewelry box design using graphic design software like Adobe Illustrator or CorelDraw. Ensure your design is compatible with the laser cutter's file format (typically DXF or AI).

-

Material Selection: Choose the ideal material for your laser cut jewelry box based on your design and desired aesthetics. Popular options include:

-

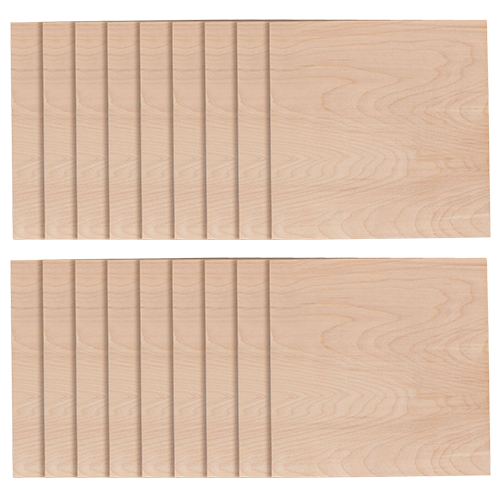

Wood: Wood offers a natural and rustic aesthetic, perfect for handcrafted or vintage-inspired jewelry. Select hardwoods like birch or maple for a smooth engraving surface.

-

Acrylic: Clear or colored acrylic adds a modern and sleek touch to your boxes. Acrylic can be engraved to reveal a frosted effect, or you can incorporate colored acrylic for a vibrant pop.

-

Leather: Luxurious and elegant, leather elevates the perceived value of your jewelry. Choose vegetable-tanned leather specifically treated for laser engraving to ensure clean, crisp cuts.

-

3. Laser Cutting and Engraving: Once your design is finalized and the material chosen, transfer the design file to the Monport 80W's control panel. Utilize the machine's intuitive interface to set the appropriate laser power, cutting speed, and engraving depth based on your chosen material. Initiate the cutting and engraving process, and watch your laser cut jewelry box come to life!

4. Finishing Touches: Depending on the material, you may want to add finishing touches to your laser cut jewelry box. For wood, consider sanding the edges for a smooth finish. Acrylic boxes might benefit from polishing with a microfiber cloth. Leather boxes can be treated with a leather conditioner to maintain their shine.

Additional Tips and Settings for Laser Cut Jewelry Boxes

Here are some additional tips and settings to consider when crafting laser cut jewelry boxes with the Monport 80W CO2 Laser Engraver & Cutter:

Material Specific Tips:

-

Wood:

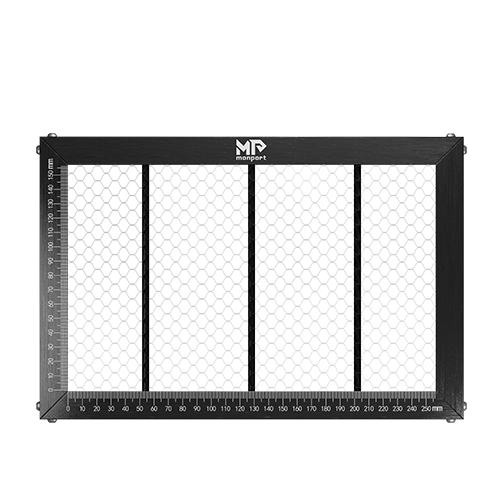

- Use a honeycomb cutting table to prevent charring on the underside of the wood.

- Experiment with different cutting speeds and laser power settings to achieve clean cuts without burning the edges. Start with lower power settings and gradually increase until you achieve the desired results.

- Depending on the wood thickness, you may need to perform multiple passes to achieve a complete cut.

-

Acrylic:

- Use masking tape to cover the acrylic surface before engraving to prevent smoke residue buildup. This can be easily removed after engraving to reveal a clean design.

- Adjust laser power settings to achieve a frosted effect or a clean cut-through on the acrylic. Lower power settings will create a frosted engraving, while higher power settings will cut entirely through the material.

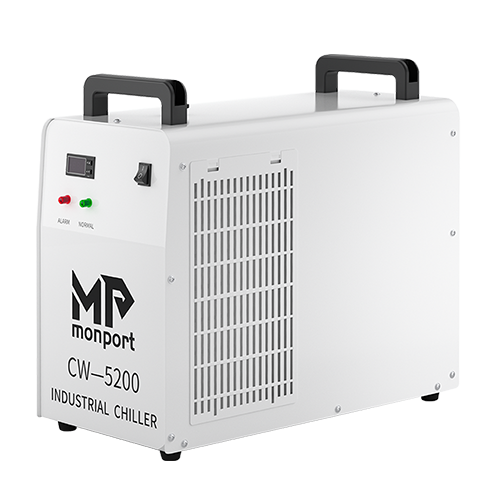

- Be mindful of ventilation, as acrylic fumes can be strong during the cutting process. Ensure proper ventilation is in place to remove fumes safely.

-

Leather:

- Choose vegetable-tanned leather specifically treated for laser engraving. This ensures clean cuts and minimal burning.

- Test laser settings on a scrap piece of leather before engraving on your final box material.

- Start with lower power settings and gradually increase to achieve the desired depth and detail without burning or overcutting the leather.

- You can achieve different visual effects on leather by adjusting the laser power and speed. Lower power and higher speed can create a light etching effect, while higher power and slower speed can produce deeper cuts.

General Laser Settings:

-

Start Low, Go Slow: Always begin with a lower laser power and slower cutting speed for your chosen material. You can gradually increase the settings if necessary but be cautious, as it's easier to remove too little material than it is to undo over-cutting.

-

Test & Refine: Experiment with different settings on scrap material before engraving your final design. This allows you to fine-tune the power, speed, and focus for optimal results.

-

Focus Matters: Ensure the laser head is properly focused for the material thickness you're cutting. This ensures clean cuts and minimizes charring or melting. The Monport 80W's autofocus feature simplifies this process.

Recommended Starting Settings (Always Test Cut First):

| Material | Laser Power | Cutting Speed |

|---|---|---|

| Wood (1/8" thickness) | 40% | 2mm/s |

| Acrylic (1/8" thickness) | 30% | 5mm/s |

| Leather (vegetable-tanned) | 15% | 1mm/s |

Additional Tips:

-

Fume Extraction: Laser cutting and engraving generate fumes. Ensure your workspace has proper ventilation to remove these fumes and maintain a healthy working environment. The Monport 80W's built-in ventilation system helps with this.

-

Safety First: Always wear appropriate safety gear, including laser safety glasses rated for the wavelength of your laser cutter, when operating the machine.

-

Software Optimization: Utilize features like layer control in your laser cutting software to assign different power and speed settings to various elements of your design. This allows for precise engraving on different depths.

Remember, these are just starting points. The optimal settings will depend on your specific material, desired cut depth, and the Monport 80W's individual performance. Always prioritize test cuts and adjustments to ensure successful results for your laser cut jewelry box projects.

By following these tips and experimenting with different settings, you'll be well on your way to creating stunning and unique laser cut jewelry boxes with the Monport 80W CO2 Laser Engraver & Cutter. Remember, the key is to start slow, test your settings, and have fun exploring the creative possibilities!

Elevate Your Brand with Personalized Packaging

By incorporating laser cut jewelry boxes into your packaging strategy, you can elevate your brand image and create a truly memorable customer experience. The Monport 80W CO2 Laser Engraver & Cutter empowers you to bring your creative vision to life, allowing you to craft unique and personalized boxes that perfectly complement your jewelry collection.

Ready to take your business to the next level? Visit our website today to learn more about the Monport 80W CO2 Laser Engraver & Cutter and discover how it can transform your jewelry presentation. We offer comprehensive resources, detailed tutorials, and outstanding customer support to ensure your success in the world of laser cutting and engraving.

Unlock a world of creative possibilities and elevate your brand with the power of laser cut jewelry boxes!

Leave a comment