Everything You Need to Know About Running a Fiber System

CODE

Introduction

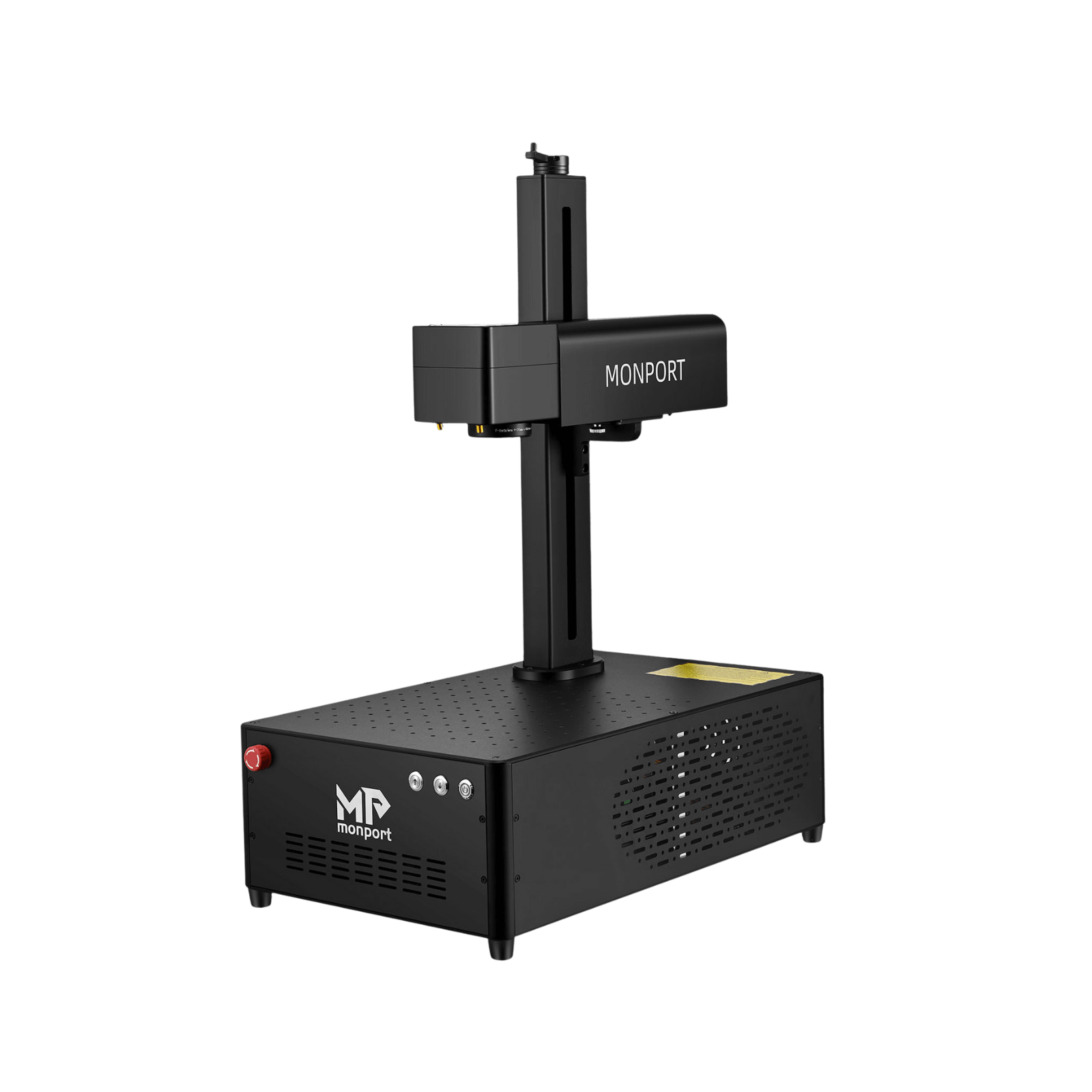

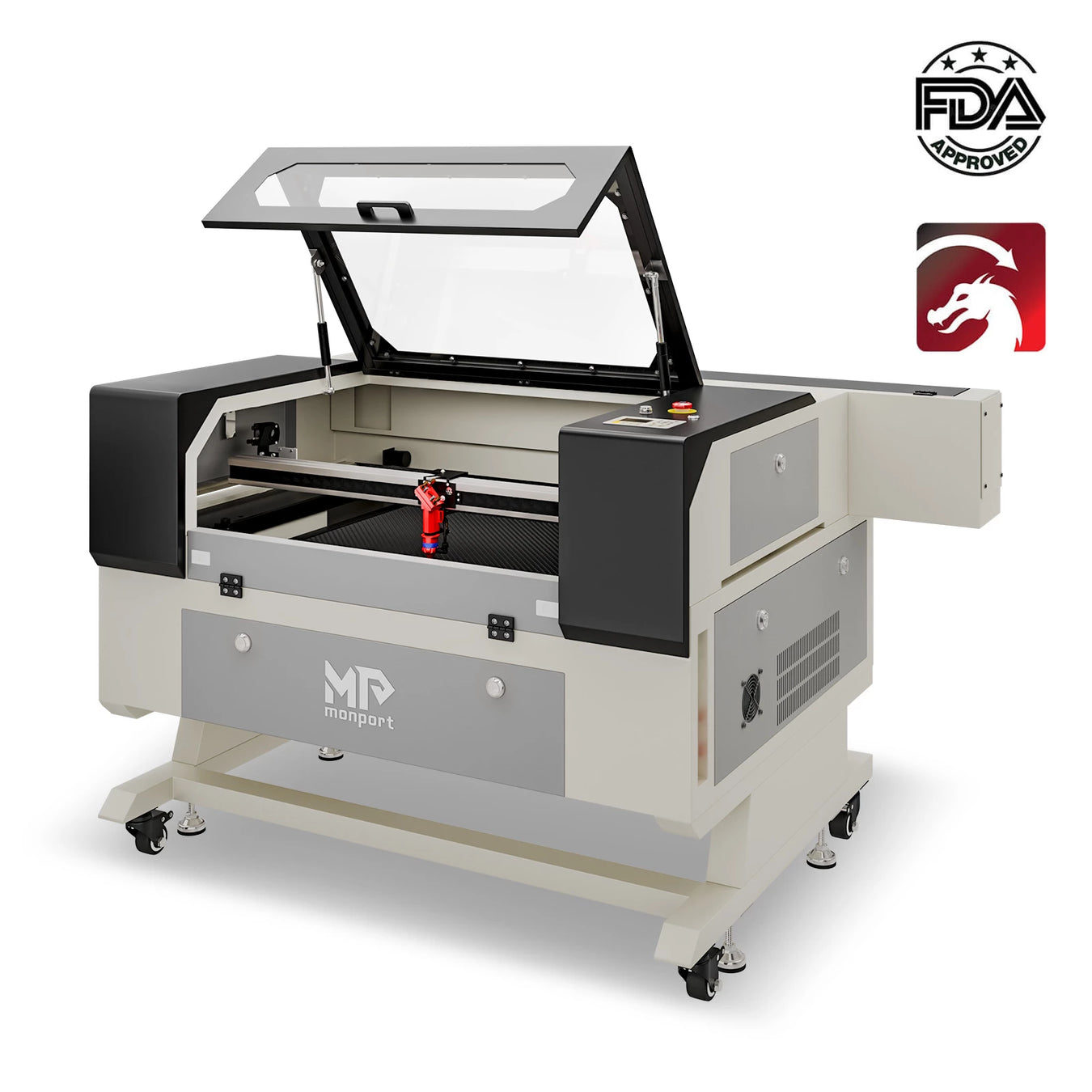

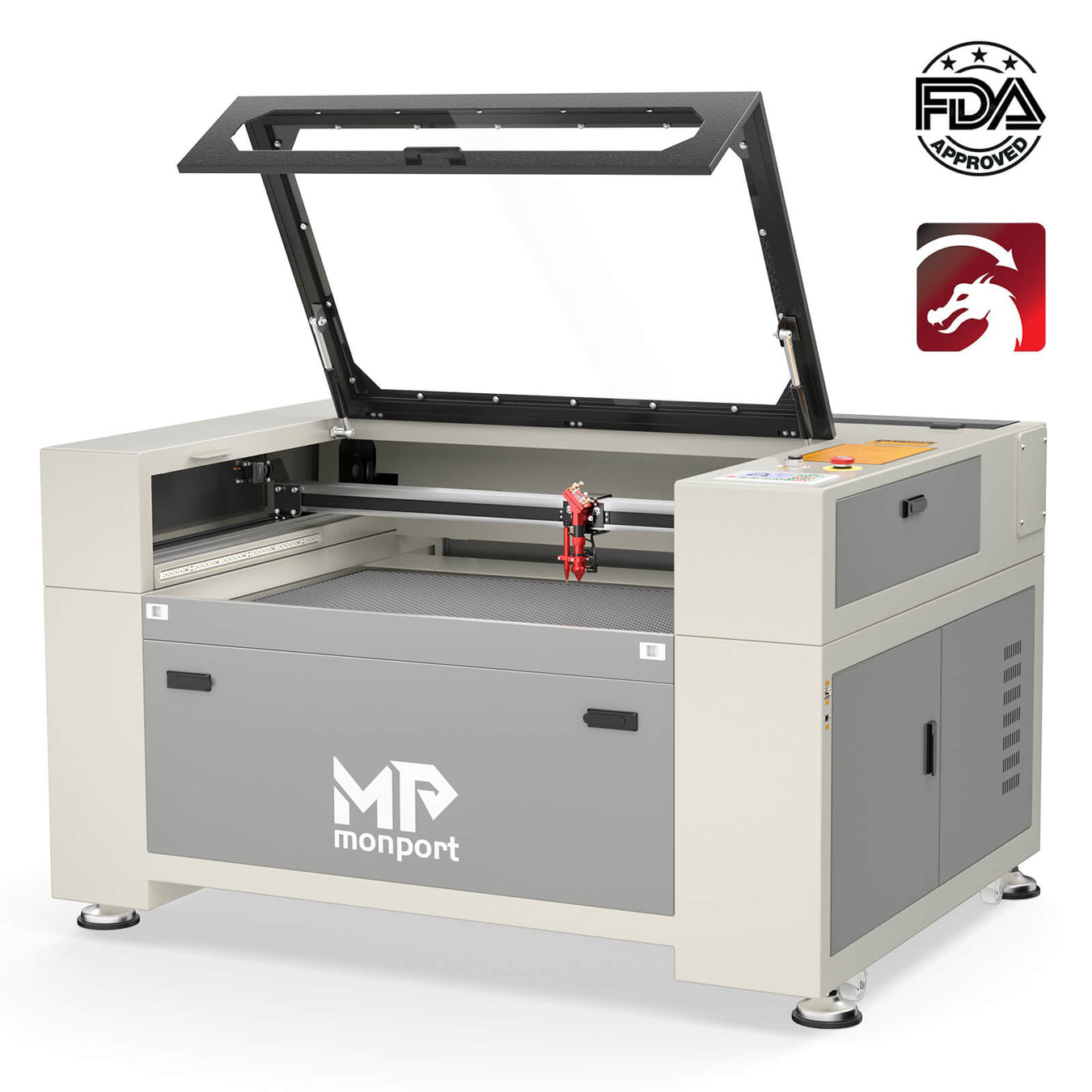

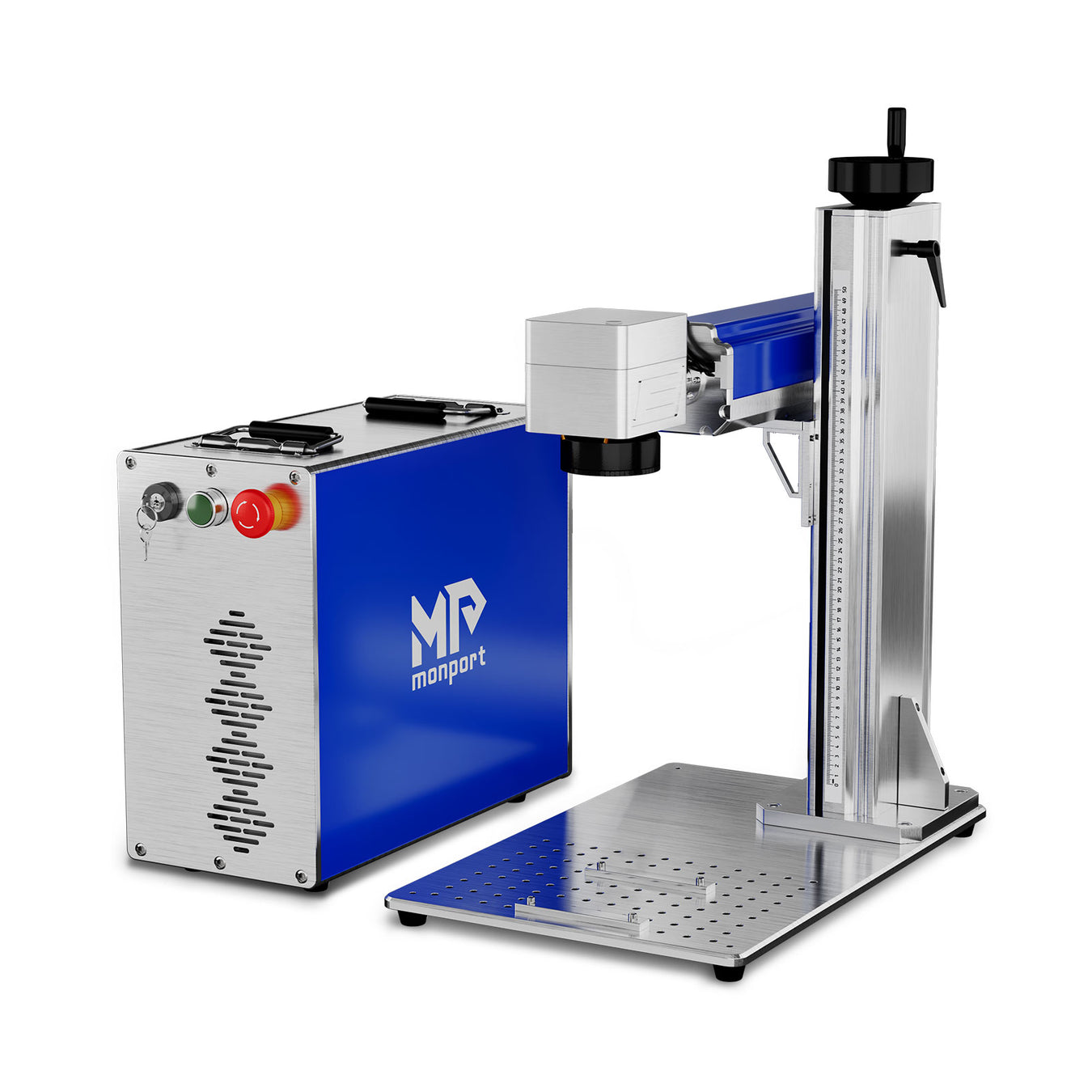

Welcome to our comprehensive Buying Guide, where we shed light on the cost considerations and explore the best pricing options for fiber lasers. Ever wondered, How much does it cost to run a fiber laser per hour? Join us as we navigate the intricacies of laser technology, focusing on the MONPORT GP20 Integrated Fiber Laser Engraver & Marking Machine with Electric Lifting. In this guide, we'll unravel the mysteries surrounding fiber laser pricing, providing insights to help you make an informed decision. Stay tuned for expert advice and recommendations on securing the best fiber laser price for your needs.

MONPORT GP20 Integrated Fiber Laser Engraver & Marking Machine with Electric Lifting

MONPORT GP20 Integrated Fiber Laser Engraver & Marking Machine with Electric Lifting

What is a Fiber Laser Machine?

Before we discuss the operating cost and the best fiber laser price, let's define what a fiber laser machine is. A fiber laser machine, specifically a fiber laser engraver and marking machine, is a tool that uses a high-powered laser beam to engrave, cut, or mark materials such as metals, plastics, and ceramics. A fiber laser machine is different from a traditional CO2 laser machine in that it uses a solid-state laser instead of a gas laser to produce the beam.

FAQs

- How much does it cost to run a fiber laser per hour?

- The cost of running a fiber laser depends on several factors such as the machine's wattage, the price of electricity, and the cost of consumables such as lenses and cutting heads. On average, the cost can range from $10 to $20 per hour of operation.

- What is the best fiber laser price?

- The best fiber laser price depends on the specific needs of your business. It is essential to evaluate the machine's capability and reliability, the quality of output, and the cost-effectiveness before making any purchase decisions. At MONPORT, we offer the GP20 Integrated Fiber Laser Engraver & Marking Machine with Electric Lifting, which is a cost-effective and reliable machine that can meet most of your engraving and marking needs.

Factors that Affect the Cost of Running a Fiber Laser Machine

- Wattage: An essential factor in the cost of running a fiber laser is the machine's wattage. The higher the wattage of the machine, the more energy it consumes, resulting in more electricity costs per hour.

- Electricity Cost: The cost of electricity varies depending on geographic location and energy provider. You must consider the cost of electricity when calculating the operating cost of your fiber laser.

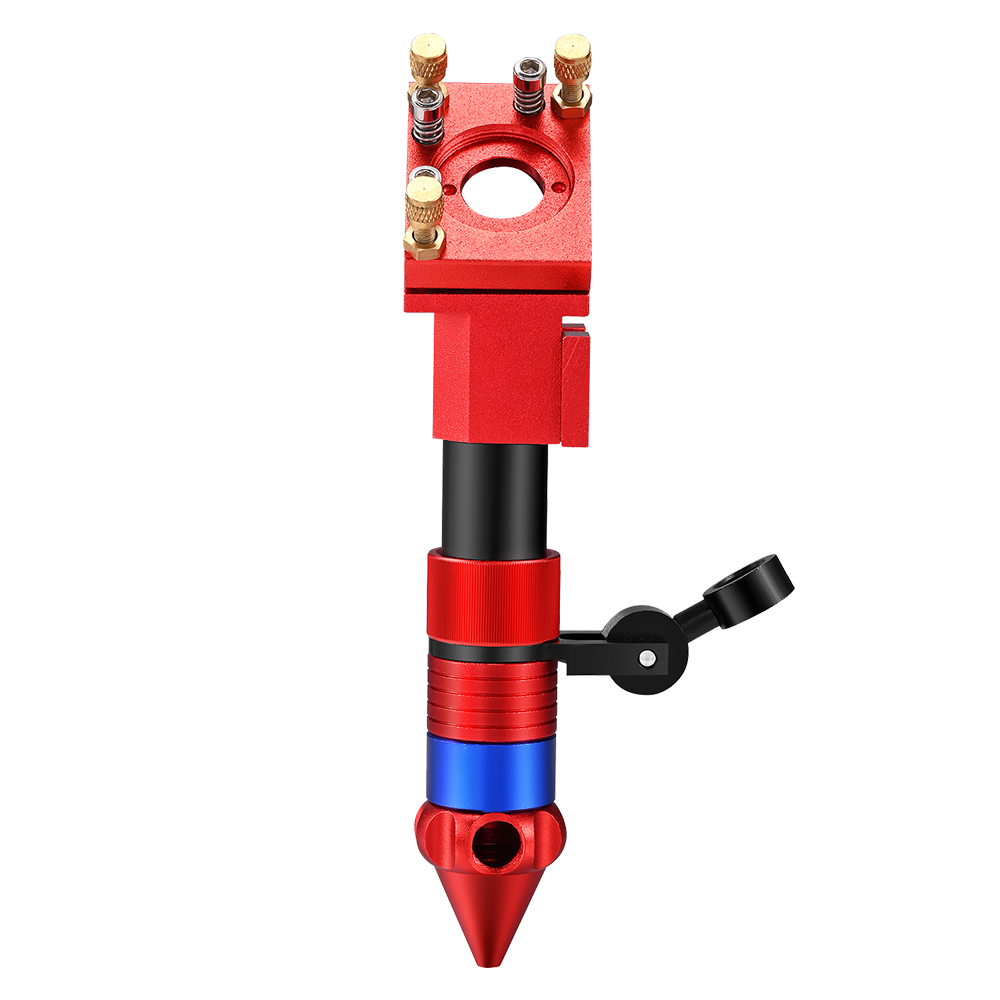

- Consumables: Consumables such as lenses and cutting heads need regular replacement, and their cost is an appropriate variable to consider when calculating the cost of running a fiber laser per hour.

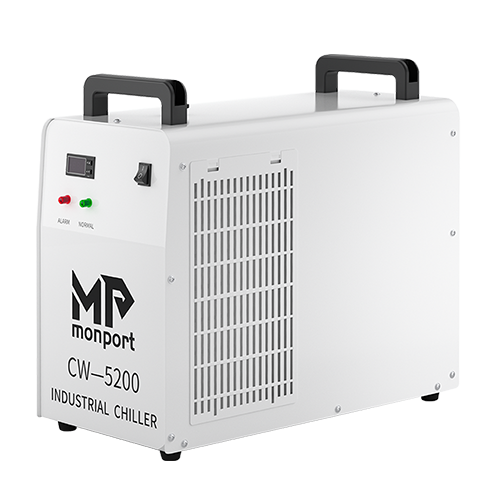

- Maintenance: Regular maintenance is essential to keep your fiber laser machine in good working condition. It has a cost that depends on the use frequency and the severity of the machinery's wear and tear.

Important Details to Consider When Buying a Fiber Laser Machine

- Machine Capability: When buying a fiber laser, consider the material, thickness, and intricacy of your workpieces. It is crucial to know the machine's performance with respect to cutting, marking, and engraving.

- Quality of Output: The quality of the output should also be considered. The sharp corners, straight edges, and clean surfaces of the output require machinery capable of maintaining the right beam quality throughout the system lifecycle.

- Safety: The safety of the machine should also be considered. Ensure that the machine has safety features such as emergency stops and safety interlocks to prevent significant injuries and machine damage.

- Maintenance and Service: The availability of maintenance and service after-purchase should also be considered. A reliable manufacturer with good customer service should offer after-sales assistance, as well as machine maintenance to manage machine wear and tear.

Takeaways

- A fiber laser machine is a cost-effective option compared to traditional laser machines.

- The cost of running a fiber laser per hour depends on various factors such as wattage, electricity cost, consumables, and maintenance.

- The best fiber laser price depends on the machine's capability and reliability, the quality of output, and the cost-effectiveness.

- When buying a fiber laser machine, consider its capability, quality of output, safety, and maintenance and service.

Conclusion

In conclusion, the cost of running a fiber laser per hour is a significant factor to consider when purchasing a machine. Still, it depends on different variables that need to be assessed based on the specific needs of your business. At MONPORT, we believe that a cost-effective and reliable solution to your quality cutting, marking, and engraving needs is our GP20 Integrated Fiber Laser Engraver & Marking Machine with Electric Lifting. Contact us today to learn more about our products and services and to request a quote.

Leave a comment