Monport vs. OmTech 60W Laser Cutter: The Power of Laser Cutting Technology

CODE

The world of laser cutting is brimming with exciting possibilities, empowering creators and businesses to bring their visions to life with exceptional precision and detail. Choosing the right laser cutter is crucial for maximizing efficiency and achieving the desired results. One big question for laser engravers, "What are the cutting capabilities of OmTech 60-watt laser cutter?"

This comprehensive guide dives into the cutting capabilities of the Monport 60 watt laser cutter and compares it to the OmTech 60W laser cutter. By analyzing key features, performance specifications, and user experience, we aim to equip you with the knowledge needed to make an informed decision for your laser cutting needs.

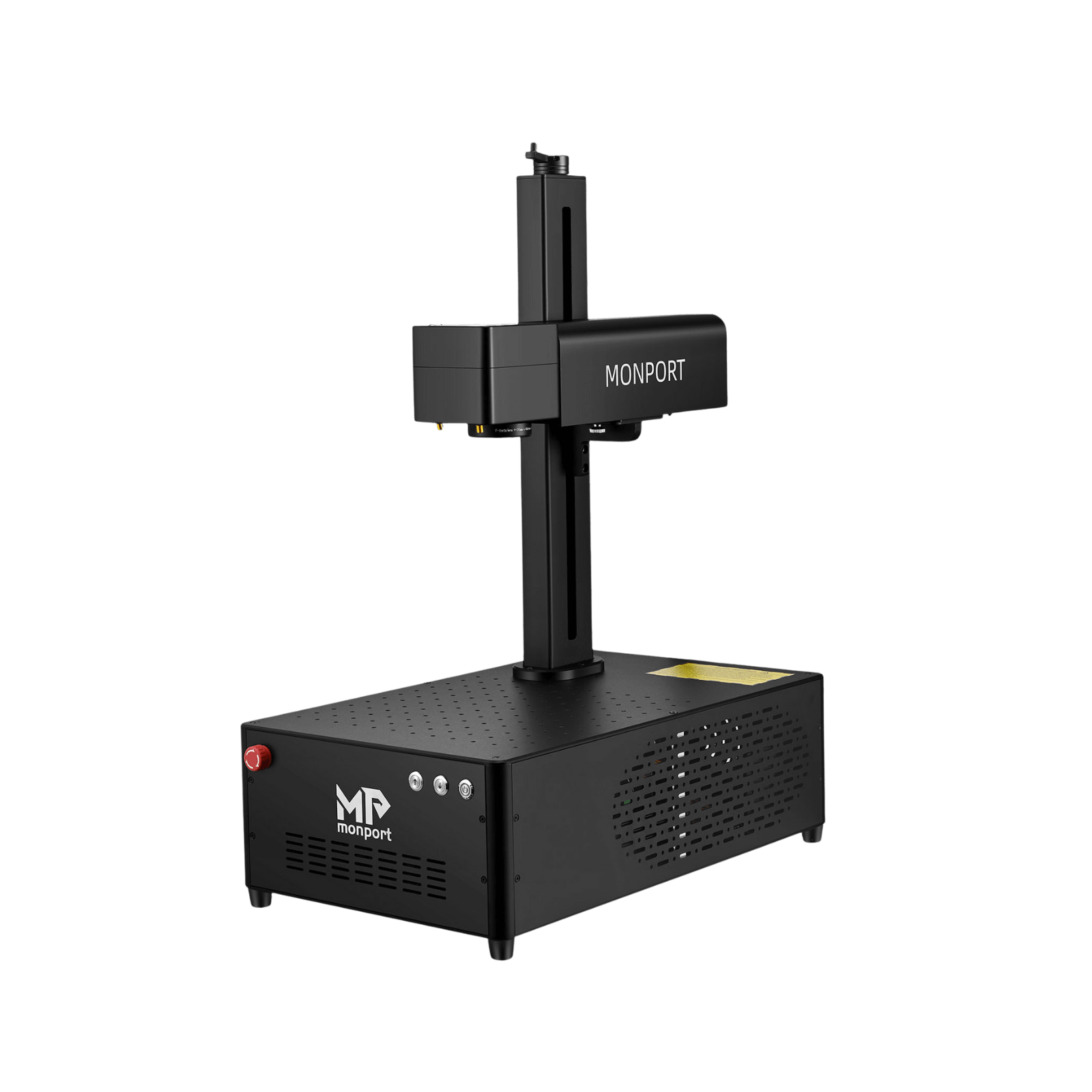

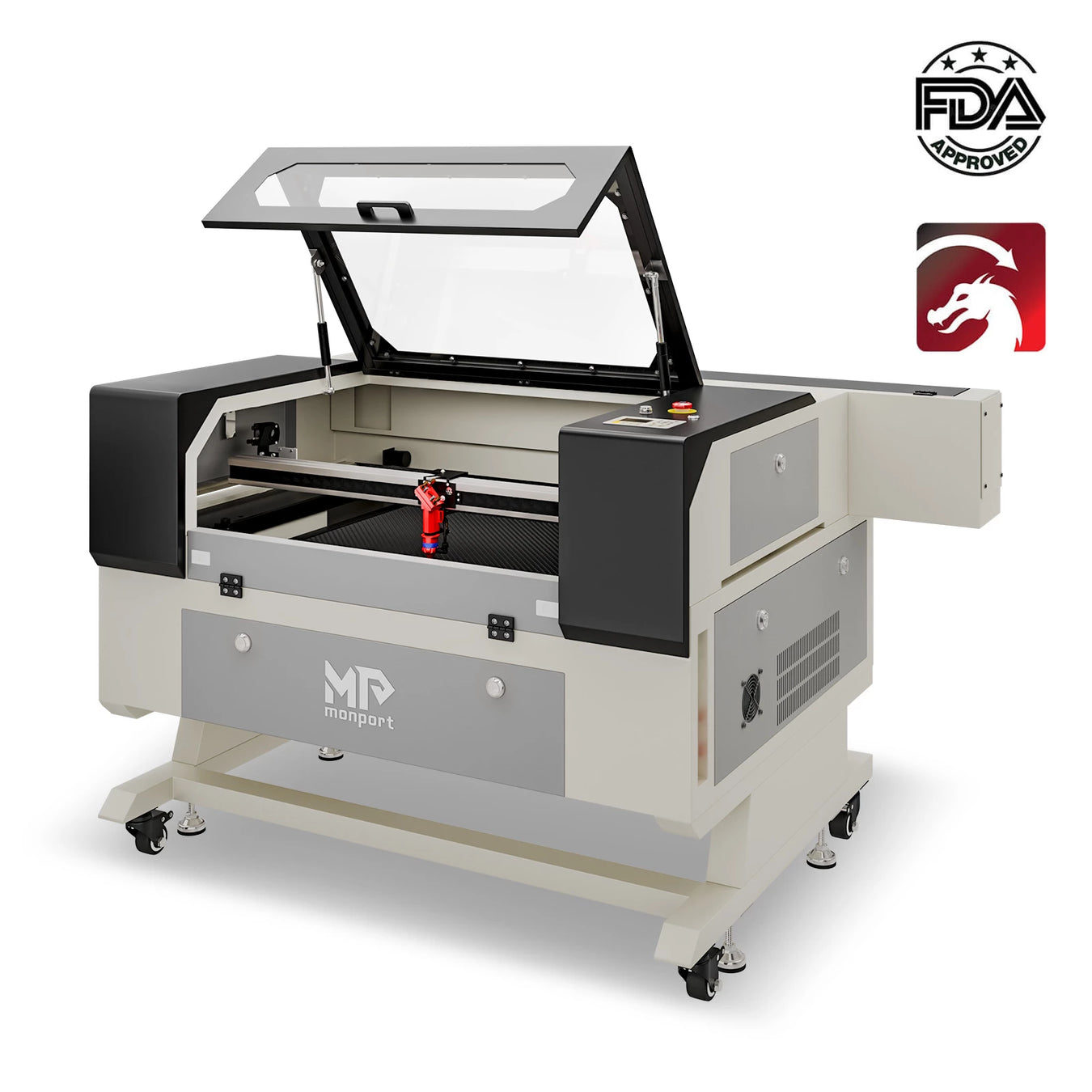

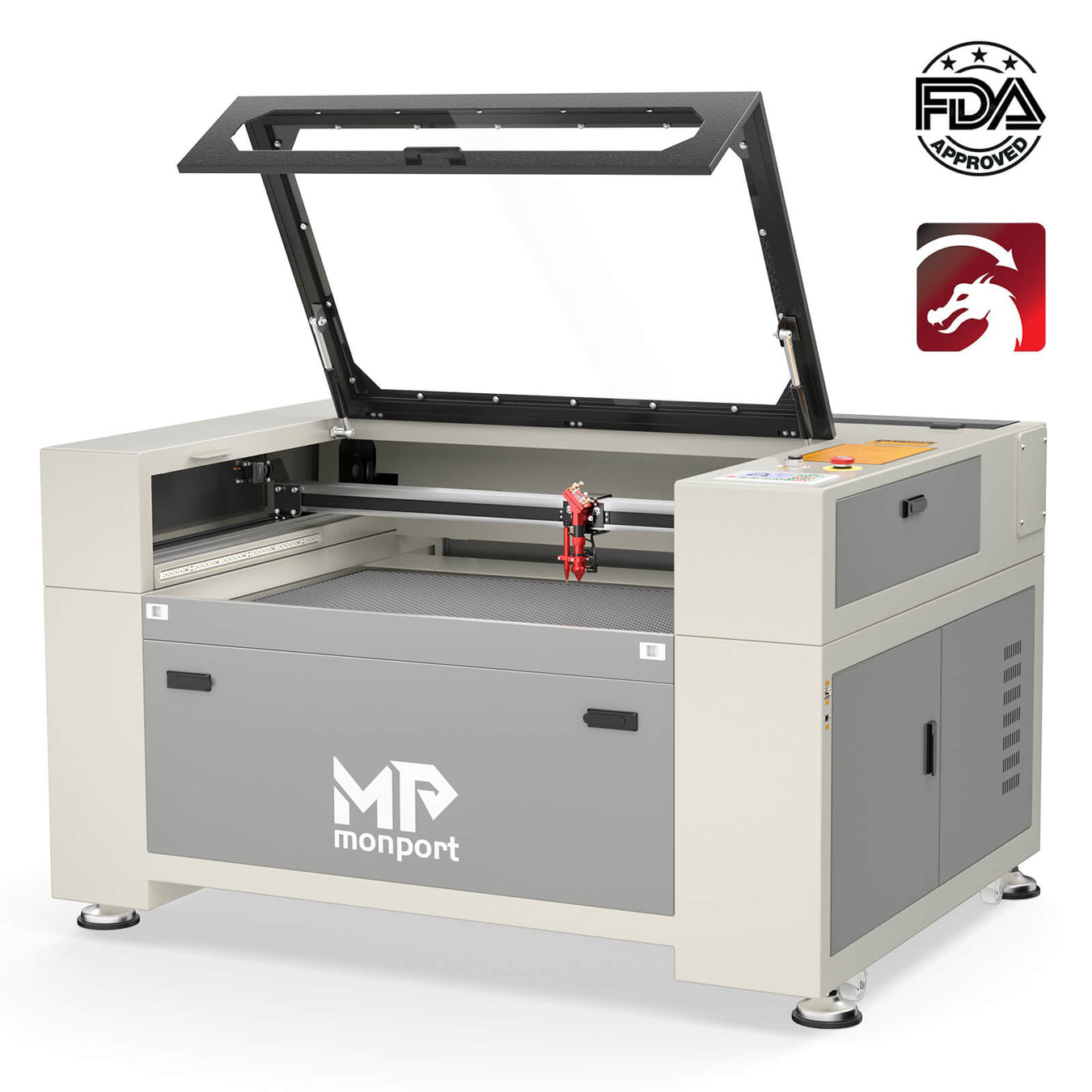

Monport 60W CO2 Laser Engraver & Cutter (28" x 20") with Autofocus

Laser Cutting Technology: A World of Possibilities

Laser cutting utilizes a focused laser beam to melt, vaporize, or ablate material, creating precise cuts along a computer-controlled path. This technology offers several advantages over traditional cutting methods, including:

- Unmatched Precision: Laser beams allow for incredibly clean and accurate cuts, ideal for intricate designs and small details.

- Versatility: Laser cutters can handle a wide range of materials, from wood and acrylic to fabric and leather.

- Minimal Material Waste: Laser cutting minimizes material waste compared to traditional methods like sawing or drilling.

- Clean Cuts: Laser cutting results in clean edges with minimal burning or charring, often requiring minimal post-processing.

- Speed and Efficiency: Laser cutters offer high cutting speeds, translating to faster project completion times.

Head-to-Head Feature Comparison: Monport 60 watt vs. OmTech 60 watt Laser Cutter

Let's begin with a side-by-side comparison of the two laser cutters, highlighting their core specifications:

| Feature | Monport 60W Laser Cutter | OmTech 60W Laser Cutter |

|---|---|---|

|

Use code BESTMP10 for 10% Discount |

|

|

| Price | $2,499.99 | $2,599.99 |

| Working Area | 16" x 24" (40 cm x 60 cm) | 16" x 24" (400 x 600 mm) |

| Max Cutting Depth | 0.59 inches (15 mm) | 0.4" (10 mm) |

| Engraving Speed | Up to 800 mm/s | Up to 600 mm/s (23.6 ips) |

| Resolution | Up to 4500 dpi | Not specified |

| Autofocus | Yes | No |

| Air Assist System | Built-in | No |

| Red Dot Pointer | Yes | No |

| Safety Sensor | Automatic shutdown sensor | No |

| Software Compatibility | LightBurn, RDWorks, AutoCAD, CorelDRAW | LightBurn, RDWorks, CorelDRAW, AutoCAD |

| Customer Reviews (average) | 4.6 out of 5 stars | 4.1 out of 5 stars |

Beyond the Specifications: Exploring the Advantages of Monport 60 watt Laser Cutter

While the table offers a clear comparison of features, it's vital to understand the practical implications of these differences. Here's a deeper look at why the Monport 60W laser cutter might be a better fit for your needs:

-

Cost-Effectiveness: Budget-conscious creators will appreciate the Monport 60W's slightly lower price point, making it an attractive option for first-time buyers or those with budget constraints.

-

Enhanced Performance: Speed and precision are paramount in laser cutting. The Monport 60W offers a significant edge with its faster engraving speed (800 mm/s vs. 600 mm/s), translating to quicker project completion times. Additionally, the potential for a higher resolution (4500 dpi) on the Monport 60 watt laser cutter allows for finer details and sharper engravings, crucial for intricate designs and professional-looking results.

-

Advanced Functionality: The Monport 60 watt laser cutterboasts several features absent in the OmTech 60W, including:

- Autofocus: This eliminates manual adjustments, saving time and ensuring consistent engraving quality.

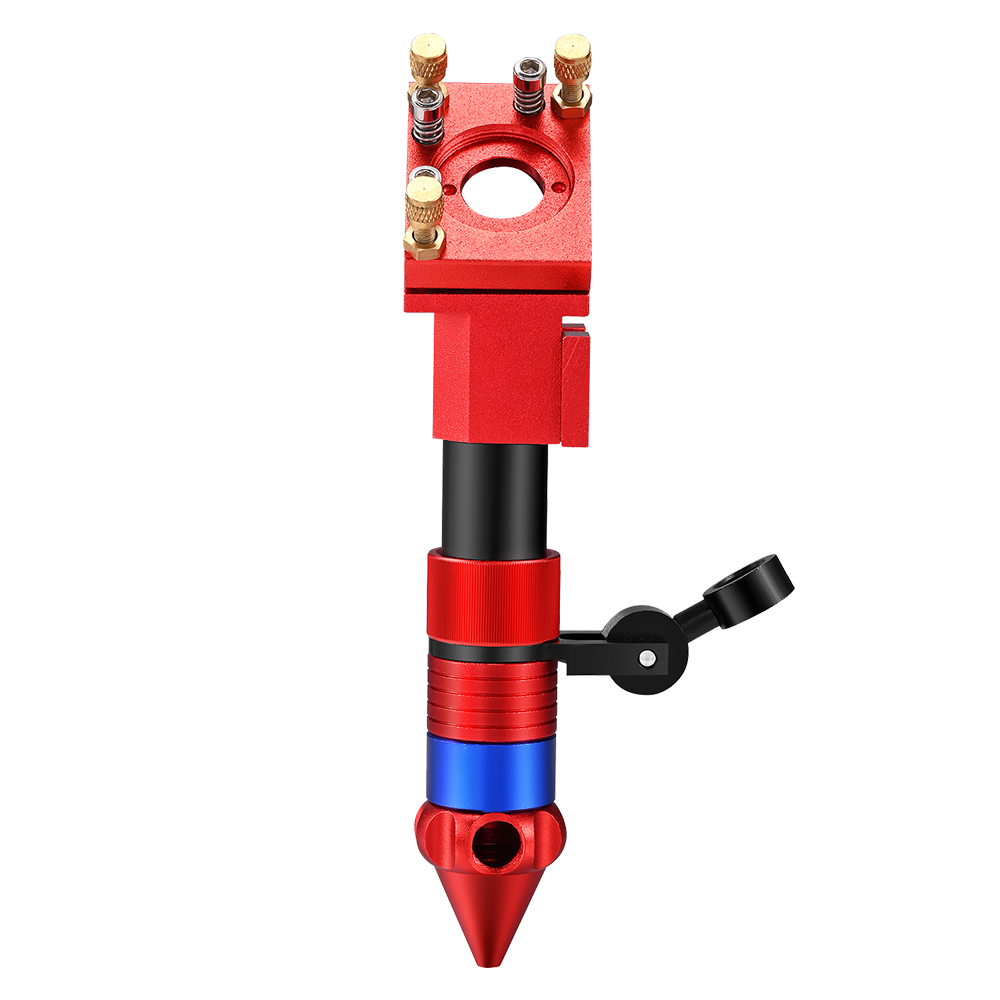

- Built-in Air Assist System: This system removes debris and fumes from the cutting area, leading to cleaner cuts and reduced post-processing needs.

- Red Dot Pointer: This visual aid enhances precision by showing the exact cutting or engraving location, minimizing errors and material waste.

- Automatic Safety Sensor: This sensor provides an extra layer of protection by automatically shutting down the machine if the window cover is opened.

- Greater Cutting Depth: The Monport 60W's maximum cutting depth of 0.59 inches (15 mm) surpasses the OmTech's 0.4 inches (10 mm), offering greater versatility for working with a wider range of materials and thicker projects.

-

Customer Reviews: Positive customer reviews for the Monport 60 watt (averaging 4.6 out of 5 stars) indicate user satisfaction with its performance and features. While the OmTech 60W also receives positive reviews (averaging 4.1 out of 5 stars), the Monport 60 watt laser cutter appears to garner slightly higher user satisfaction.

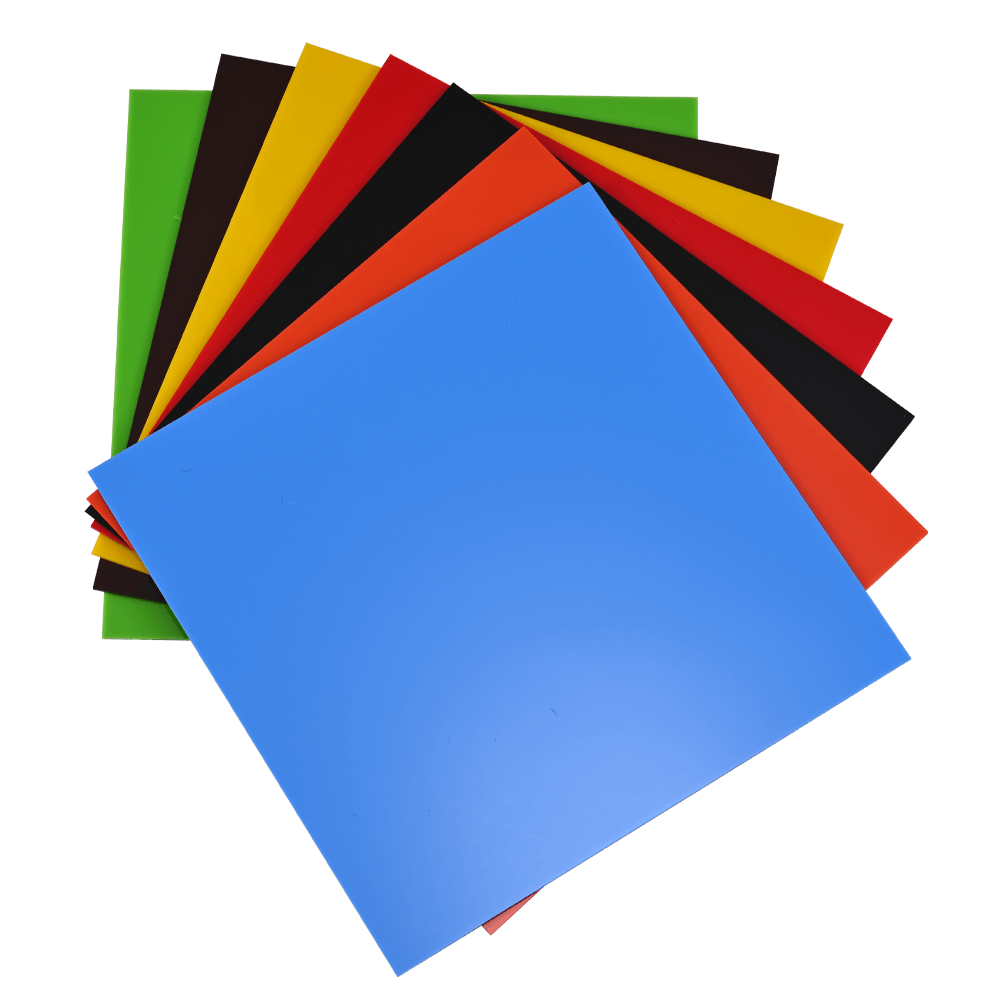

Choosing the Right Material for Your Laser Cutting Project

The success of your laser cutting project hinges on selecting the appropriate material. Here's a breakdown of some popular materials compatible with CO2 laser cutters, like the Monport 60 watt:

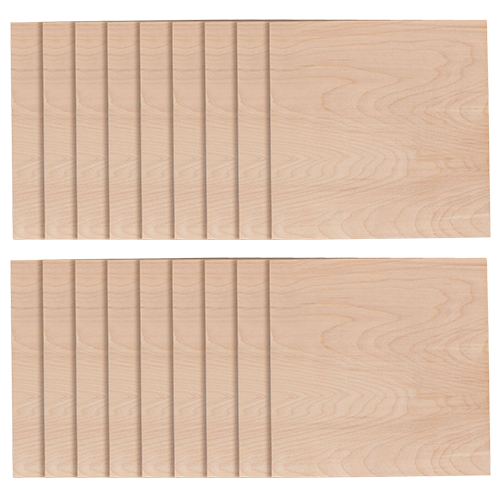

- Wood: Wood is a versatile material for laser cutting, ideal for crafting signs, plaques, decorative items, and more. Different wood types have varying cutting parameters, so experimentation is key.

- Acrylic: Laser cutting acrylic creates stunning results, perfect for signage, keychains, jewelry, and home décor projects. Acrylic comes in various colors and thicknesses, offering design flexibility.

- Leather: Laser cutting leather allows for precise personalization and intricate details on wallets, belts, phone cases, and other leather goods. Leather thickness and tanning processes affect cutting parameters.

- Fabric: Fabric laser cutting is ideal for creating custom clothing appliqués, patches, and intricate textile designs. The type of fabric and its fiber content determine the appropriate cutting settings.

Settings and Parameters: Mastering the Art of Laser Cutting

Laser cutting involves specific settings that influence the cutting outcome. Here are some key parameters to consider:

- Laser Power: Power determines the intensity of the laser beam and its ability to cut through material. Higher power is needed for thicker materials.

- Cutting Speed: Speed dictates how fast the laser beam travels along the cutting path. A slower speed allows for deeper cuts in thicker materials.

- Pulse Rate (Pulse Frequency): This refers to the number of laser pulses delivered per second. A higher pulse rate can create smoother cuts but might require lower power settings to avoid burning the material.

- Air Assist: An air assist system blows compressed air onto the cutting area, helping remove debris and fumes, leading to cleaner cuts.

Achieving Stunning Laser Cuts with Your Monport Laser Cutter

With the Monport 60 watt laser cutter's advanced features and user-friendly software, achieving stunning laser cuts is within reach. Here are some tips and tricks to optimize your results:

- Experiment with Settings: Start with recommended settings for your chosen material and gradually adjust them based on your observations. Every material reacts differently to the laser, so find the sweet spot between cutting depth, speed, and edge quality.

- Utilize High-Quality Materials: Using high-quality materials free from impurities ensures consistent cutting results and minimizes imperfections.

- Maintain a Clean Machine: Regularly clean your laser cutter's mirrors and lens to ensure optimal laser beam focus and cutting performance.

- Test Cuts on Scrap Material: Before starting your final project, test your settings on a scrap piece of the same material to avoid wasting valuable material.

- Embrace Software Features: Leverage LightBurn's advanced features like test cuts and layer editing to fine-tune your designs and achieve exceptional results.

Maintenance for Consistent Performance

Proper maintenance is crucial for ensuring your Monport laser cutter operates at its peak performance and delivers consistent results. Here are some key maintenance practices:

- Cleaning: Regularly clean the lens and mirrors of your laser cutter using appropriate cleaning supplies. Dust and debris can accumulate and affect cutting performance.

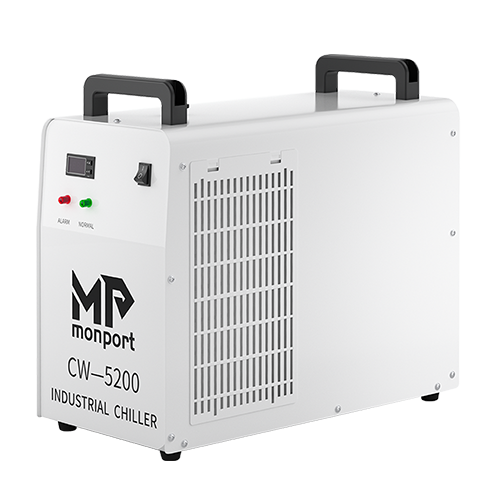

- Water System Maintenance: If your Monport laser cutter utilizes a water cooling system, ensure the water level remains within the recommended range and change the water periodically to prevent overheating.

- Alignment Checks: Periodically check the laser beam alignment to ensure it remains focused for optimal cutting precision.

- Software Updates: Keep your laser control software updated with the latest versions to benefit from bug fixes and performance improvements.

By following these tips and tricks, you can unlock the full potential of your Monport 60 watt laser cutter and create stunning, professional-looking projects with exceptional precision and detail.

Conclusion: Unveiling Your Creative Potential with Monport Laser Cutters

The world of laser cutting offers endless creative possibilities for hobbyists, entrepreneurs, and businesses alike. Choosing the right laser cutter empowers you to bring your visions to life with exceptional results.

This comprehensive guide has explored the capabilities of the Monport 60 watt laser cutter, highlighting its advantages over comparable models. With its impressive features, user-friendly software compatibility, and focus on enhanced performance, the Monport 60 watt emerges as a compelling choice for creators seeking a versatile and feature-rich laser cutting solution.

Ready to unleash your creative potential with the power of laser cutting? Visit the Monport Laser website today to explore the Monport 60 watt laser cutter and discover a world of possibilities. They offer a wealth of resources, including:

- Detailed product information: Dive deeper into the technical specifications and features of the Monport 60 watt laser cutter.

- Material compatibility guide: Learn which materials are ideal for laser cutting with your Monport laser cutter.

- Tutorial library: Gain valuable knowledge and skills through comprehensive laser cutting tutorials.

- Project ideas: Spark your creativity with a vast collection of inspiring laser cutting project ideas.

Don't wait any longer! Invest in a Monport 60 watt laser cutter and embark on a journey of creative exploration and exceptional results.

发表评论